Features

It is suitable to form BOPS, HIPS, PS, PVC, and PET plastic sheets, etc., which can produce various boxes, dishes, trays, bowls, and lids, such as food boxes, cake boxes, fast-food boxes, supermarket trays, oral liquids trays, etc.

Specifications

|

No |

Item |

Data |

|

1 |

Forming area |

610*620mm |

|

2 |

Forming depth |

100mm |

|

3 |

Sheet thickness range |

0.10-1mm |

|

4 |

Sheet roller diameter |

710mm |

|

5 |

Air pressure |

0.7Mpa |

|

6 |

Water consumption |

10 Liters/min(15-20℃) |

|

7 |

Air consumption |

1800 Liters/min |

|

8 |

Production Speed |

600-1200 recycles/hr. |

|

9 |

Voltage |

AC380V±15V, 50HZ |

|

10 |

Mould plate heating power |

6kw |

|

11 |

Heating plate power |

15kw |

|

12 |

Weight |

2000kg |

|

13 |

Dimension(Forming part) |

4410*1290*2130mm |

Details

Application

Machine Construction

Machine Made Samples

Machine Details Introduction

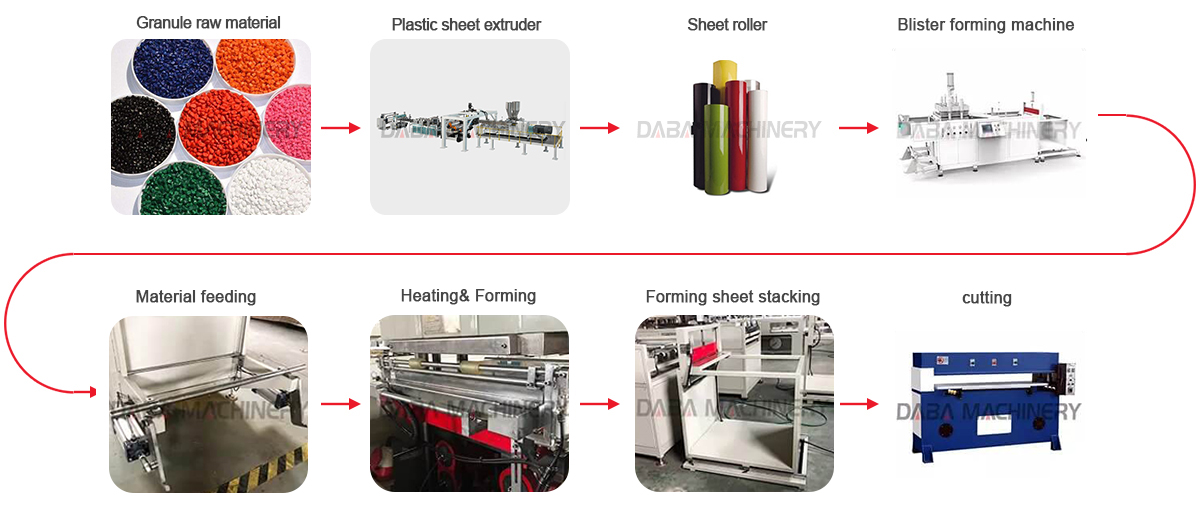

The machine is combination of mechanical , electrical and pneumatic components, and it combines the material sending,heating, forming into one process. The final products need a cutting machine to cut one by one.

The whole system is controlled a micro PLC,which can be operated in maninterface.And it aslo has capability of reliable,quality jarless, fault few.

◆ Feeding Part

The feeding part of the machine is control by double cylinder.

◆ Heating and Forming Part

This machine adopts place contact-heating technology.Heating and forming are carried out in the single station at the same time. This King of forming method is very power-saving, and the floor area of this machine is aslo small, which is very easy to operate.

◆ The machine adopts servo motor drives the sheet transport system

It has quickly production capacity,highly utilization ratios of plastic sheet. Low air consumption and maintenance,nice final ready products, it is a new generation ideal package equipment.

◆ Operation buttons and displays of the machine

◆ Formed sheet cutting

After the material is formed,the formed will be cut by the cutting device(the red part)and then stacked at the back.

◆ Formed sheet reference

◆ About the cutting for the product

Need an independent cutting machine or the on-line automatic cutting machine to cut the product piece to piece.

Machine & Mould Manufacturing

We have a complete production line and professional engineers,combined with advanced technology and mature experience, to produce high-quality machines.

Following molds for reference :

Our company

DABAPLAS company always adhere to the principle of "survive by quality,relying on science and technology to promote development", adopts a modern

technological layout,implements scientific management and completes the quality system throughout the production process.

Our products mainly include:Plastic positive and negative in-mould cutting thermoforming machine,Full automatic BOPS contact- heat plastic thermoforming

machine, Multi-station positive and negative thermoforming machine, Automatic plastic cup thermoforming machine, Cup counting and packing machine,

Automatic vacuum forming machine, Multi-station vacuum forming machine,Automatic PP/ PET/PS/ PVC extrusion, Online crusher, Plastic bag making machine,etc.

We will make sure that all our clients are completely satisfied in terms of quality of the products delivered to them. View more>

The Exhibitions We Have Participated In

Certification

Customer feedback

Every DaBaplas machine is quality proven, superior in design and produced as per the highest quality standards. Before leaving our factory, it is tested and retested for performance, productivity and durability. Because of good quality and service, we have won a good reputation among domestic and international customers.Our products sell well in Asia (such as India,Thailand, Vietnam, Indonesia, Malaysia, Sri Lanka), the middle east (Iran, Pakistan, Saudi Arabia, Kuwait),Europe(Russia, Rumania,Bulgaria, Italy)Africa (Nigeria, Guinea, Congo), North America and South America.We hope to establish good and long-term business cooperation with customers from all over the world. If you have any inquiry about our machines, please feel free to contact us.

Successful Case

The machines are running well in our customers’ factories.We have become a regular partner of many customers.

Service

1. Pre-sales Service

DABAPLAS MACHINERY has a specialized and efficiency working team. If you are new on the plastic forming machine area,we are glad to give you specialized suggestion of the whole work.

2. Shopping Service

DABAPLAS MACHINERY has a specialized and independent department to arrange the shippment. We will prepare all the necessary documents so as to arrange the delivery smoothly,

we cooperate with the most famous shipping company in China,they could provide the best and economic shipping ways to destinaion.

3. Installation Services

Installation Services are avaliable with DABA Company machines. We could dispatch technician to the Buyer's factory for installation and preparation of the machines.

The buyer needs to supply the round trip tickets,food,hotel cost and daily salary.

4. Cilents Training Services

The buyer could aslo send your own technician come to DABAPLAS factory to learn how to operate machines,Our technician will teach and train the learners hand by hand till he operate machine by himself.

5. After Sales Service

DABAPLAS Company machines guarantee time is one year. Many easy broken spare parts will be prepared in tool box together with machines.

Package and shipment

1. Our standard packing method is film wrapping.

2. Wooden case packing can be provided as required and the cost will be charged.

3. The delivery date of machine is within 45 days per set.

4. Shipment in Ningbo port or Shanghai port, China

FAQ

Q:What's your delivery date?

A:Usually finish the production within 45 days after received your 30% advanced payment, actually need to check according our stock & production plan.

Q: Terms of payment?

A: We accept T/T with 30% in advance and 70% before shipment. Also we could accept L/C at sight.

Q: How many days will the finish installing ?

A: We will finish installation and training within 15days.

Q: How long is your machine's warranty period?

A: All our machine have one year guarantee, starting from the day when finished installation.

Q: How could we do after one year warranty period?

A: We provide 1 year warranty. Within the warranty period, we provide free machine parts and repair service but not including shipping cost if it is not caused by human factors. After 1 year, we provide lifetime service with affordable charge.

Q: How many worker do we need to operate those machines?

A: Usually one machine needs 1-2 operators.

Q: Could you supply raw materials?

A: We can help you to order the raw materials and arrange the shipment together with machines.